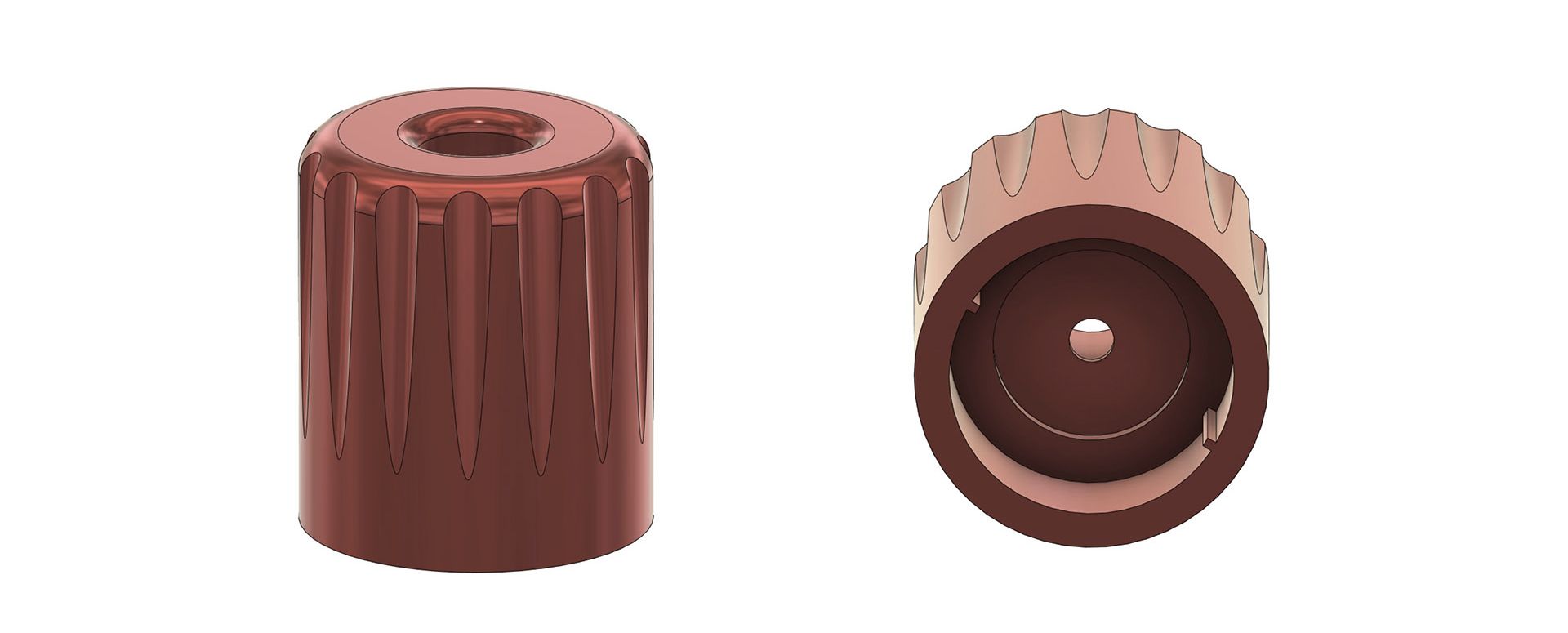

Canon TS-E Knobby

Call me fussy, but poor ergonomics drive me mad. During a long work day I want my equipment to be easy to handle. One piece of kit that I have not been a fan of are the tiny shifts knobs on my Canon 24mm and 50mm TS-E lenses. Canon seems to be well aware of the issue and includes a knob extension with their lenses. The original extension makes the knob a tiny bit bigger, but does not quite go far enough. When handling the knobs in hot (sweaty) or cold (gloves) conditions, they are not exactly easy to operate.

Finished 3d MODELS in AUTODESK FUSION 360

This is further exacerbated by using a Rogeti TS-E Frame. Don’t get me wrong, I love these frames for many reasons described in my previous articles, but they make the shift knob even harder to reach. Since I could not find any aftermarket solutions, I resigned myself to coming up with my own solution: I would design and 3D print my own knobs.

Print-READY FILE, each squiggle is a row of 0.2mm thin plastic extruded at 200 degrees

A few months ago I fell down the rabbit hole of 3D printing and its millions of free models on exchanges like Thingiverse. There, I found one knob extension that looked promising, but its screw-less friction fit did not stay securely enough in place. And so, with no prior experience in 3D modelling, I sat down to figure out my own solution.

A few hours of careful measurements with digital callipers, a slow learning process in Fusion 360, and a bunch of failed prototypes later, my Canon TS-E Knobby was finished. It fits perfectly over the Canon knob and is securely held in place with the original screw. Since my 24mm and 50mm TS-E lenses look almost identical, I colour-coded them with my TS-E Knobbies.

I have used the TS-E Knobby for several months without any issues. It has worked perfectly in combination with Rogeti TS-E frames, and should be even more substantial when used without one. You can find the 3D model free for personal use on Thingiverse.

Canon TS-E Knobby on Thingiverse